The Differences Between Coil, Wire And Comb Binding Elements

- Share

- Issue Time

- Oct 23,2017

The Differences Between Coil, Wire And Comb Binding Elements

To get the best results for all your binding projects, you need two critical pieces of information. First, know how you want your finished document to look and perform; second, understand what each binding element has to offer in creating your desired outcome.

Here is a quick comparison of coil, wire and comb bindings.

Coil (Spiral) Binding

For flexible binding that offers many options and can handle rough treatment, choose coil binding and a professional coil punching machine. Here are some of the benefits:

1.Wide choice of colors

2.Metal and plastic coil options

3.Plastic coils are less easily distorted

4.Ends of metal coil can be crimped to prevent page slippage

5.Finished documents lay flat and fold back 360 degrees

6.Works for documents of up to 300 pages

7.Three different coil lengths: 36 inches, 12 inches, and 11 inches

8.A good solution for odd-sized materials

9.Can work with 5:1 hole-punch patterns (5 holes per inch) and 4:1 patterns (4 holes per inch) but these sizes are not interchangeable

10.A coil punching machine easily creates different punch patterns

Coil binding is a good choice for documents that will be mailed and allows for many types of custom covers on finished documents. Because you must determine the punch pattern before starting, coil binding can take a little extra time so consider using a precise, high-quality coil punching machine.

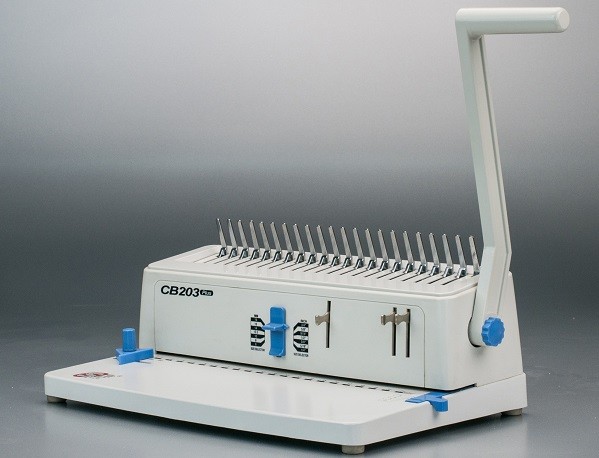

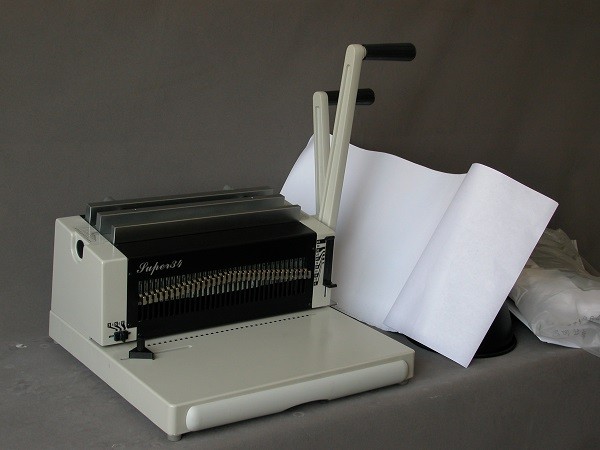

Comb Binding

Comb binding uses a plastic comb to bind documents and is very popular for many reasons. One is the development of the electric comb binding machine which saves time. The other is that plastic binding can be opened to insert or remove document pages and then put back onto the document, which lowers the cost of materials. Here’s more:

1.Finished document lays flat but cannot open back on itself (360 degrees)

2.Binds documents from 5 pages to 300 pages

3.Lots of color choices and custom lengths

4.Plastic spine can be customized with company name and/or document name through silk screening

5. Can be placed on documents manually or with an electric comb binding machine

Wire Binding

As with coil binding, completed documents can lay flat, open 360 degrees, and will mail easily. Wire binding is permanent so document pages stay in place, but this eliminates the option for editing after binding.

There are two types of wire binding: Double Loop Wire Binding and Wire Comb Binding, and each produce professional results.

Double Loop Wire/Double-O-Wire Binding:

1.Many color varieties

2.Binds documents from ¼ inch to 1¼ inches thick

3.Custom wire lengths are available

4.Allows for custom document covers

Wire Comb Binding:

1.Uses same hole pattern as plastic comb binding so one punching machine and electric comb binding machine can handle both kinds of materials

2. Binds documents up to 1 inch thick

3.Can be more expensive than double loop binding wires

The drawback of wire binding is that thinner documents use a 3 hole-per-inch pattern (3:1) while thicker materials need a 2:1 punch pattern, requiring two punch die assemblies.

Once you know your specific document needs and match them with the right binding elements, you can consistently produce professional documents that keep your company a step above the rest.