Newest Automatic multi Roller UV coating machine with automatic paper feeder system

- Price

- US $7500

- Model

- U-18AI

- MOQ

- 1 piece

Item specifics

- embossing width

- 460mm

- embossing thickness

- 0.2~2mm

- embossing speed

- 0-10m/min

- Max paper size

- 450*600mm

- Min paper size

- 210*150mm

- Paper grams

- 150~400g/m2

- Speed

- 0~40m/min

- Power

- 1kw

- Voltage

- AC220V/50HZ

- N.W.:

- 170kg

Review

Description

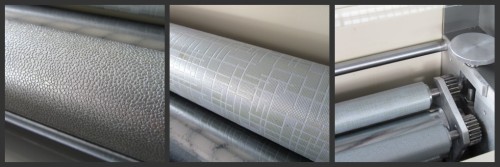

Newest Automatic multi Roller UV coating machine with automatic paper feeder system U-18AI

Introduction:

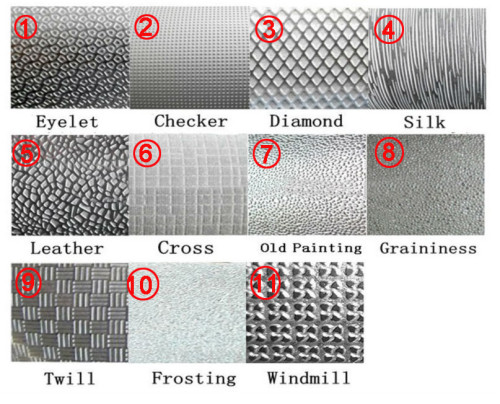

Widely usage range

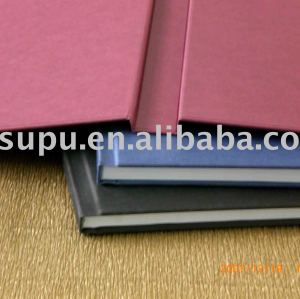

Special material made double rolling worm design, use isolated sealed ultraviolet light fast dry, very safety. The thickness of the pictures is adjustable, very suitable for Album, Advertising, handcraft paintings, prints etc.

PS: Assemble infrared ray device is optional.

1.applicable to small size paper automatic feeding,support working with UV coating machine ,laminator

2. paper platform automatically rising up

3.the safety limit function for paper platform rising up and down

4. conveyor beltautomatic impaction and side guide paper lacator confuguration

Feature

Widely using for coating magazines, printed photos, book covers, calendars, cards, product samples, packing boxes, etc.

1. To solve the traditional tedious method for changing of roller axis. Using advanced PLC and smart microprocessor control device to increase production efficiency and reduce labor costs.

2. Auto paper feeder system. Hands free for changing of roller of axis.

3. Applicable for coating laser printing pictures, ink printing pictures, paper with adhesive on the back, etc. The coated paper can resist water, damp, aging and ultraviolet ray.

4. Glossy and matte liquid are available. Coats the paper with either glossy UV liquid, or matte liquid for a classy look.

5. Special roller design that helps to coat the paper evenly.

6. Low cost. Exquisite rolling deign making the UV liquid affect even, the cost of the UV coating only between 0.35-0.50RMB/m² .

7. Infrared drying equipment. Cooling fan system. Fit for drying job after the lay on UV oil or soluble.

8. UV drying UV radiation makes the UV oil harden and become resistant to wear, and promote the glossiness of the paper surface. Equipment with fast cooling equipment, avoids paper curling.

9. Available size: 18inches(480mm), 24inches(650mm), 32inches(820mm), 36inches(930mm)