Electric Single Spiral Coil Binding Machine for office use PC330SE

- Model

- PC330SE

Item specifics

- Power

- Electricity

- Width

- 330mm

- Pitch

- 5mm

- Hole type

- round, oval

- Punching thickness

- 25sheets

- Binding Thickness

- 120sheets

- Number of Punch Pins

- 64

- Disengageable Die Pins

- 64

Review

Description

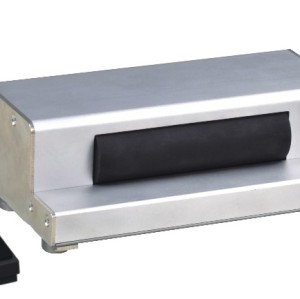

Electric Single Spiral Coil Binding Machine for office use PC330SE

PRODUCT DESCRIPTION

Binding format: spiral,coil

Punch capacity: 22 sheets (80g)

Bind capacity: 450sheets

Number of punch pins:64

Edge distance can be adjusted, hand powered

Alloy construction make it durable to keep you away from trouble service for years

Foot pedal operated electric binding to speed up punching ability

Side margin control provides and keep sheets aligning easy

Top position roller for binding easy and comfortable.

With document measurement to measures files' thickness and guide to select best coil size option

TECHNOLOGY DATA

| MaxBind Capacity (20# paper) | 450Sheets |

| Max Punch Capacity (20# paper) | 22Sheets |

| Binding Format | Coil |

| Punching Method | Electric |

| Binding Method | Electric |

| Punching Format (Vertical/Horizontal) | Horizontal |

| Punch and Bind Capability | Yes |

| Max Punch Length | 330mm |

| Max Binding Length | 330mm |

| Number of Punch Pins | 64 |

| Disengageable Die Pins | 64 |

| Waste Compartment | Yes |

| Side Margin Control | Yes |

| Motor | 230V,50HZ/120W110V,60HZ/120W |

WORKSHOP

CERTIFICATION

FAQ

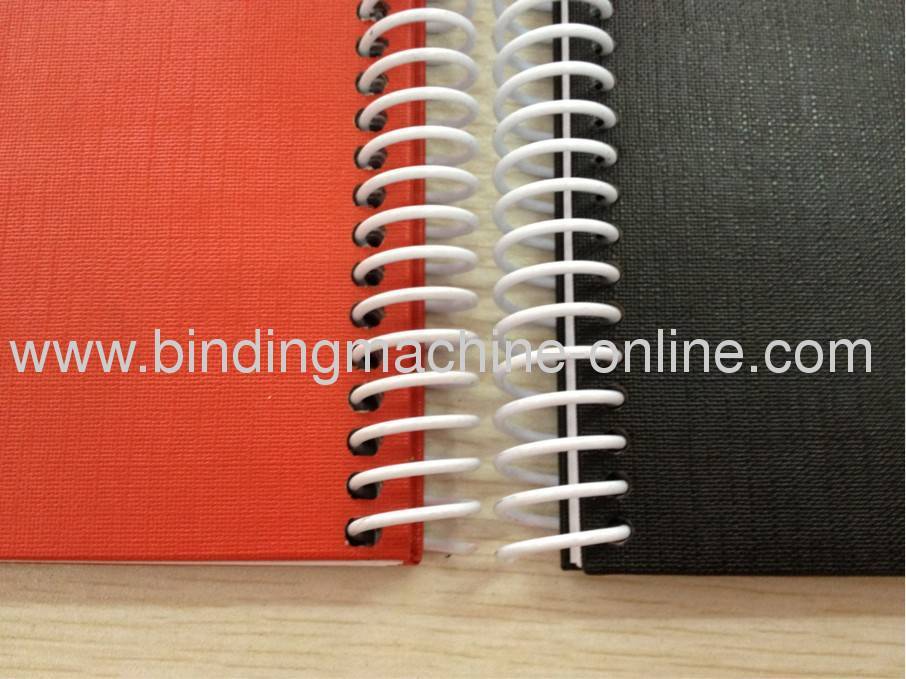

Oval hole and round hole comparing in coil inserting

For the coil punching and coil binding machine ,our company have the new type of hole which is oval hole .This kind of hole is very popular in U.S.A .

What is this oval hole advantage ? Today i would like to share my comments with you .Compare to the traditional round hole ,oval hole is much difficult in Production but has the better effect on coil inserting especially for inserting the thick sheets .

You can see the convient an comfortable from the video when inserting .But after inserting ,oval hole also has his advantage which is much easier for turn over .

Our compnay has the oval hole for our nw coil binding machine and the detail sharp of oval hole is as follows

:

If you want to learn more about our oval hole ,pls contact with us freely and it is our pleasure to talk and discuss with you !

ABOUT US

1.All of our electric binding machine ,we get CE ,CETL ,SAA ,CB certification and for the electric machine ,

2.we did the testing fot the binding machines for 300,000 times punching

3.we can guarantee for 100,000 times punching for the electric machine

Now our machines exported Germany ,Italy .France ,UK ,Switzerland ,Spain,Turkey ....North America and south America .

Also export to Korea and Japan and also other more than 80 countries .