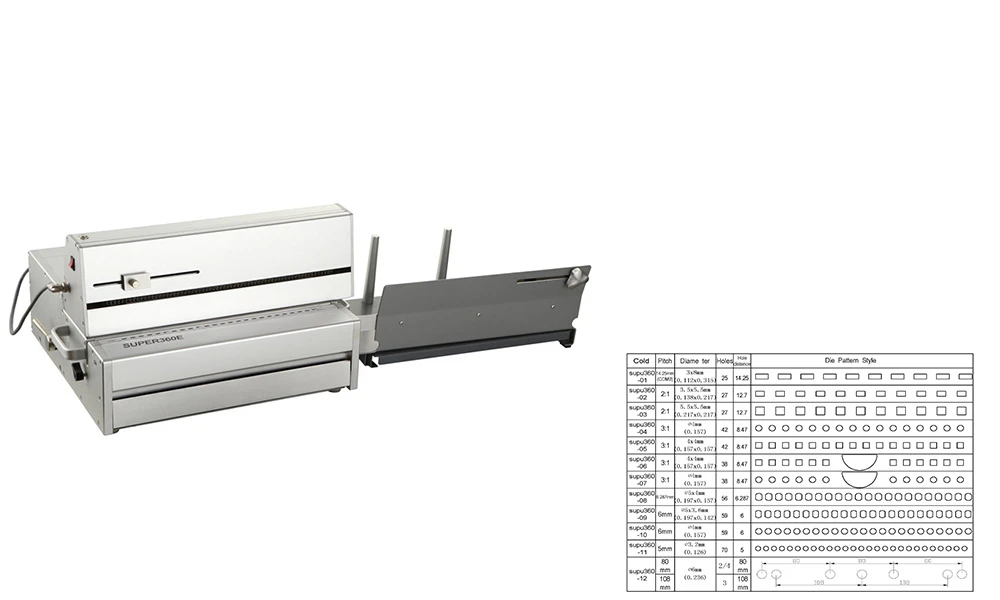

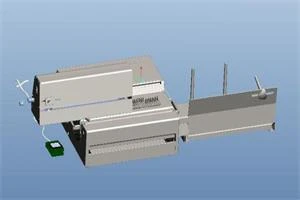

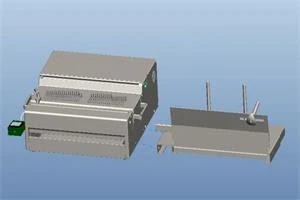

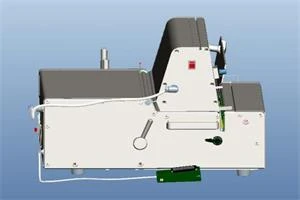

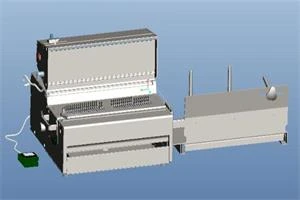

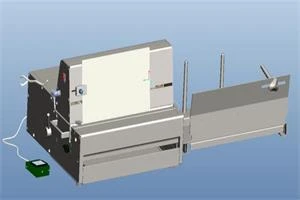

SUPU Semi-Automatic Interchangeable Dies Punching Machine SUPER360E

- Model

- SUPER360E

Item specifics

- Power

- Electricity

- Width

- 430mm

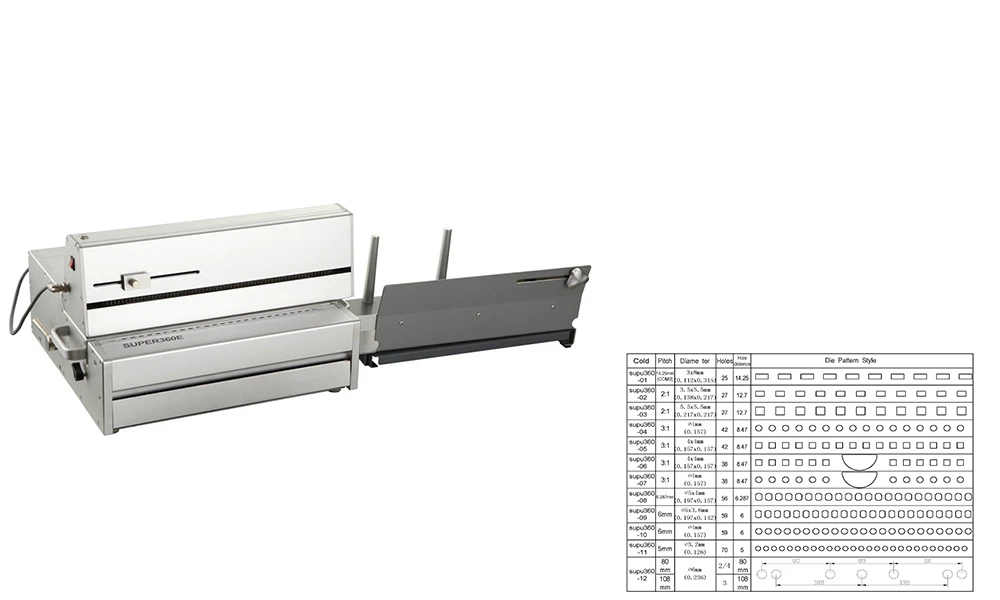

- Pitch

- on request

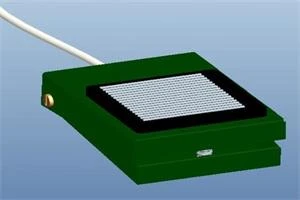

- Hole type

- on request

- Punching thickness

- 25—35sheets

- Binding Thickness

- on request

- Number of punch pins

- depending on the die

- Disgagement punch pins

- depending on the die

Review

Description

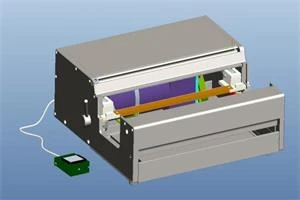

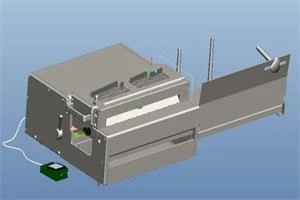

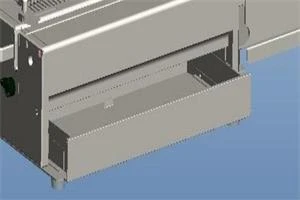

Document measure to determine which comb size to be used All aluminium construction make it durable and many years worry free High capacity waste container requires emptying less frequently